Our design principles are durability, user-friendliness, repeatability, and datum consistency.

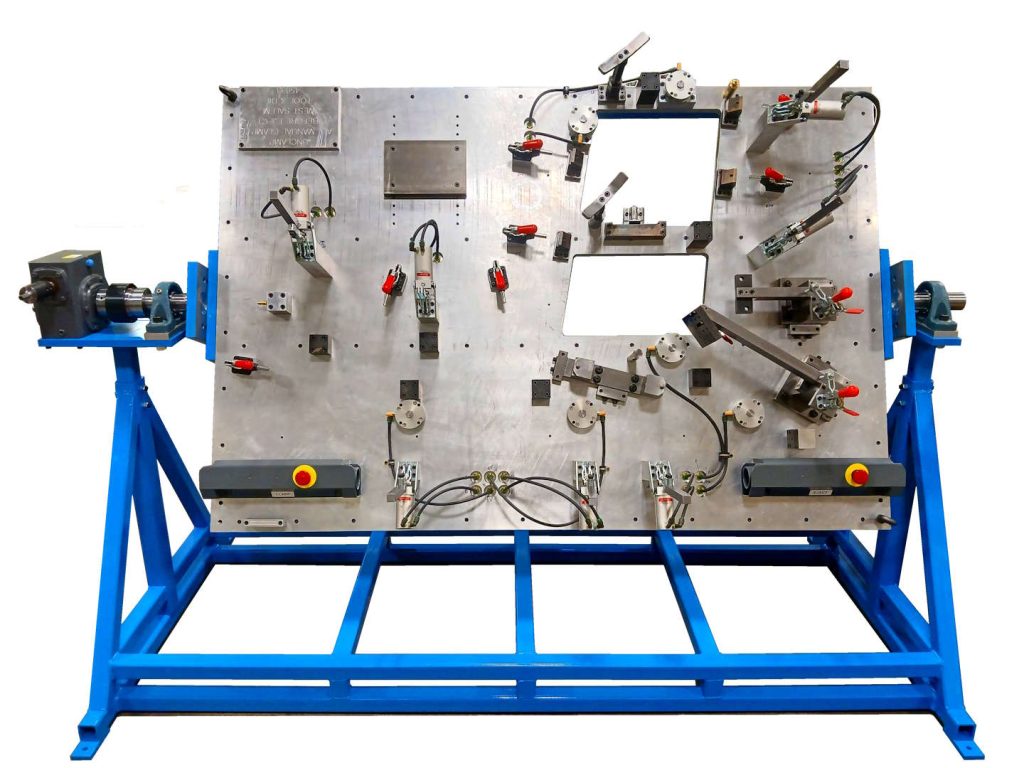

Increase fabrication rates and improve the repeatable consistency of weldments with high-quality welding fixtures.

To get the process started, send us a CAD model of your part with a weld drawing.

A project engineer will get back to you shortly with a concept fixture and cost estimate.

Welding Fixtures

West Salem Tool and Die designs and builds fixtures of many types:

• Stationary table-top fixtures, or rollover fixtures

• Fixtures with either manual or pneumatic clamping

• Robotic welding fixtures, or fixtures designed for human welders

Send in your drawings on our RFQ page. We’ll get back to you with a rough proposal design and a quote. And then, if you like what you see, we’ll proceed from there.

ROBOTIC WELDING CELLS

For robotic welding cells, a typical starting point is to acquire something like the Miller 1100SS. Once you know the dimensions of your cell and the reach of the robot arm, we’ll design a weld table that maximizes the potential of the cell. Since a robotic cell is a big investment, it often makes good sense to design a double-sided weld table.

From our site near La Crosse, WI, we deliver welding fixtures to companies across North America. Don’t hesitate to contact us for a quote or proposal if your company is physically distant from us, because we can easily do design reviews with screen-shares online.